What tools should be in a professional workshop?

What tools should be in a professional workshop?

What tools should be in a professional workshop? A well-arranged and stocked workshop makes work much easier. Useful advice is to keep tools and small items in special cabinets or containers. A workshop lamp or flashlight can be used to illuminate the room. Among the useful tools you can distinguish, among others: a set of wrenches, a drill or tongs.

Where to keep the tools?

Of course, it can be said that tools can be kept everywhere. However, every man will confirm that his own workshop strengthens motivation and gives joy. It also improves the comfort of work, because in a specially designed room it is much more convenient to perform your duties. How to arrange a functional workshop?

Special shelves, shelves and cabinets will come in handy. They are used to store large tools, such as drills or soldering irons. In small rooms, special workshop walls work best – they do not take up much space, and at the same time allow you to organize the workshop space. Their wall mounting is possible thanks to special brackets that guarantee stable mounting. Wheeled cabinets are also an interesting solution. They take up more space than those hung on the wall, but they give the opportunity to easily move them from place to place.

In addition to special cabinets, it is also worth investing in boxes and containers. Thanks to this, the storage of things will become more orderly – a set of special keys can be kept in one box, and drills in the other. This is especially important when storing small items – screws or nails, which can get caught in tools. It is better to avoid clutter in the workshop, because it only delays the work carried out.

What should every DIY person have on hand?

What is needed in a real DIY workshop is the river theme. We will especially look at tools that will be useful to amateurs (and professionals) to repair a car.

• Flat wrench set – when choosing this item of equipment, it is worth paying attention to the number of products in the set, quality and manufacturer.

• Socket wrench set – is as important as flat wrenches. Having them in your workshop, it is also good to invest in a rattle that makes working with them easier.

• A set of screwdrivers – it’s hard to do anything without them. Everyone has them in their home, which is why they also cannot be missing in the DIY workshop.

• Hammer – works in every workshop. It is worth having two pieces on hand – one large, for thick screws and the other small – for elements of a smaller size.

• Combination pliers – help you get to hard-to-reach places and perform activities that require physical strength and a firm grip.

• Drill – when choosing it, you should pay attention to its power. Standard parameters that allow you to do most of the tasks are 600 to 1000 W.

• Car cosmetics – taking care of your car, also outside, is a very important activity that should not be neglected. That is why all kinds of car cosmetics are a very important element of car workshop equipment.

How to ensure proper lighting in the workshop?

Good quality lighting is particularly important for workshops. Only clear, eye-friendly light ensures that all work is done well. What’s more, in this case the eyesight is protected and does not get tired so quickly.

What is better to choose: a flashlight or a workshop lamp? Flashlights are more convenient to use – they can be moved from place to place or taken with you if the need arises. In turn, workshop lamps give a more stable light source, and working with them is more convenient – mounted on the ceiling do not need additional support and are perfect if all repairs are carried out inside the workshop.

All larger tools such as lifts, assembly machines or balancers are described in other articles on the blog, we invite you to read.

Car lift – 5 tons. Scissor or Column one?

Car lift – 5 tons. Scissor or Column one?

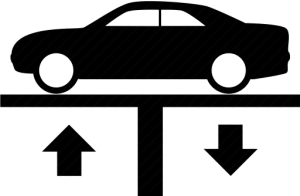

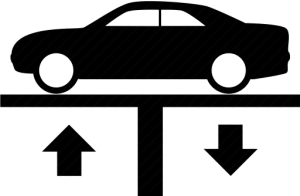

When creating a car workshop or during expansion, we ask ourselves “Car jack, how many tons of lifting capacity and, above all, what kind.” These options should be separated in an appropriate way, because they are affected by many factors.

Usable space and, of course, the budget will be the most important factors here. In the case of a small workshop, the scissor lift will do much better, which colloquially says “takes up as much space as nothing.” However, it can be a drawback that scissor lifts are slightly more expensive than column ones. The price is influenced by, among others, comparable performance, compactness sought after by many workshops and a lifting capacity of 5 tons.

Usable space and, of course, the budget will be the most important factors here. In the case of a small workshop, the scissor lift will do much better, which colloquially says “takes up as much space as nothing.” However, it can be a drawback that scissor lifts are slightly more expensive than column ones. The price is influenced by, among others, comparable performance, compactness sought after by many workshops and a lifting capacity of 5 tons.

If there is more space in the workshop, you can easily think of a lift with at least two columns, with a lifting capacity of five tons. Unfortunately, “single columns” usually close in the range of about 2.5 tons of lifting capacity. Therefore, a two-column lift, which enjoys incredible popularity due to its simplicity of use, may prove to be the best solution. It is worth paying attention to the security aspects, i.e. de facto security.

As everyone knows, work is first and foremost. Nowadays, two-column and scissor lifts offer a number of protections such as latches or emergency systems in the event of a power outage.

There is one more factor to everything – mobility. There are 5 ton scissor lifts that can be moved at their discretion. If the user anticipates that the lift will be needed, for example, in two places, the scissor lift becomes a very suitable choice.

In terms of functionality, here the two-column lift offers greater freedom of action for the mechanic as the car is raised on its feet. In the case of a “scissor”, the entire ground settles on the ramps, hence it is harder to reach some places. Ultimately, however, it can be guaranteed that both lifts will meet their assumptions, regardless of choice.

— Michał N. Adam

Twin Busch – Car Lifts

Twin Busch – Car Lifts

There are many companies on the current workshop equipment market. However, there are few reliable and above all safe equipment for servicing the car workshop. Twin Busch Germany GmbH is one of the companies that enjoys incredible satisfaction and a full guarantee of security.

Twin Busch is a medium-sized company founded in 1997 with headquarters located in Bensheim (Germany). This company also has many of its branches spread around the world. The jacks manufactured by Twin Busch are known for their excellent price-quality ratio, reliability and guarantee of customer satisfaction.

A renowned brand of car lifts

Car jacks found in workshops and outside provide full access to the vehicle. This translates into convenient repair work. The use of single, double, four-column and scissor lifts streamlines a number of other activities such as: chassis maintenance, wheel replacement, body painting. The functionality of this type of equipment in car workshops is ambiguous, which is why the selection of a suitable device should be preceded by a specific interview. In this way, the lift will meet our expectations and will perfectly adapt to any space. Twin Busch offers all types of car lifts, including single column, two column, four column, scissor and even motorcycle.

All machines manufactured by Twin Busch have thought-out and proven safeguards in such a way that the user can operate the garage without fear. For lifts, the most common protection will be a ratchet system on the columns. As soon as the vehicle is raised, press the lock button, which will lock the platform on the “teeth”. If only the user adheres to all established safety rules contained in the manual and general OHS, then there is a 100% guarantee of its safety. All norms and standards are confirmed by world-renowned TÜV, ASA, ISO, WDK and SEMA certificates.

All machines manufactured by Twin Busch have thought-out and proven safeguards in such a way that the user can operate the garage without fear. For lifts, the most common protection will be a ratchet system on the columns. As soon as the vehicle is raised, press the lock button, which will lock the platform on the “teeth”. If only the user adheres to all established safety rules contained in the manual and general OHS, then there is a 100% guarantee of its safety. All norms and standards are confirmed by world-renowned TÜV, ASA, ISO, WDK and SEMA certificates.

Not only car lifts

The Twin Busch brand has many other specialized car lifts, workshop machines, such as tire changers, wheel balancers and more other useful accessories. We invite you to familiarize yourself with the assortment of this company, which specializes primarily in the production of car lifts.

— Michał N.Adam

Truck and agricultural tire changer, how many inches?

Truck and agricultural tire changer, how many inches?

The assembly machine is a basic tool used in vulcanization plants. It allows you to remove and install tires on the rims. There are different models for such devices, and everything depends of course on the specifics of the plant. The most versatile are truck tire changers that allow operation on vans tires as well as tractors and other agricultural equipment. What scope of service should have such equipment?

The assembly machine is a basic tool used in vulcanization plants. It allows you to remove and install tires on the rims. There are different models for such devices, and everything depends of course on the specifics of the plant. The most versatile are truck tire changers that allow operation on vans tires as well as tractors and other agricultural equipment. What scope of service should have such equipment?

The best choice for large vehicles

In fact, if a mechanic wants to provide comprehensive service for truck and agricultural tires in his workshop, the choice is relatively simple – most tire changers available on the market support rims with a maximum diameter of 26″, where the wheels reach 56″ or even 63″. Sometimes, however, and this is not enough. If the budget allows (and such devices can be up to twice as expensive as smaller counterparts), it is worth choosing the largest tire changers that handle rims with a diameter of up to 56″. The dimensions of the wheels in this case can reach up to 90″. With such equipment, you can be sure that no situation will come as a surprise.

Are larger devices paying off?

Having a plant that only occasionally handles bulky vehicles, you don’t have to buy expensive assemblers of the largest sizes. However, if such clients occur relatively often, it is necessary to choose the best. The purchase of such a device can be an excellent investment – a larger range of services means, of course, less competition. And it should be noted that the largest assembly machines are also the most versatile. With one product you can handle almost any type of tire.

— Conture

Double column, hydraulic or screw car lift?

Double column, hydraulic or screw car lift?

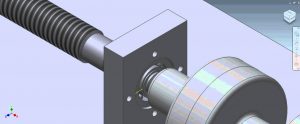

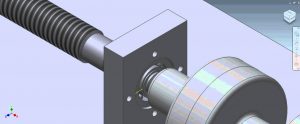

Double column, hydraulic or screw jack? A two-column lift is one of the most commonly used equipment of this kind in car workshops. It allows for a relatively large range of applications. One of the most important issues when choosing the right device is the preferred drive. Often, the first choice among mechanics turn out to be screw jacks, also called electric or electromechanical. However, hydraulic drive is gaining more and more popularity. Which option is better to choose when arranging your own workshop?

Screw drive – solid construction

The biggest advantage of this type of lift is the simplicity of the structure. Thanks to the uncomplicated structure, the parts rarely get damaged, and even in the event of certain problems, it is easy to find spare parts and make self-repair. Screw lifts are, however, relatively loud and expensive to use – energy is used to power the device throughout its operation.

Hydraulic drive – reliability and convenience of work

Hydraulic lifts also do not have a very complicated construction. The whole mechanism works thanks to oil-powered pumps. Such equipment is quieter, and does not consume energy when leaving the vehicle – the weight of the vehicle is simply used here. It is also more stable and works faster than screw models. Hydraulic jacks are also considered to be more reliable.

When choosing a lift for your workshop, consult experienced mechanics. Despite their habit of electromechanical drive, many of them emphasize the superiority of hydraulic jacks, which are less emergency and better suited to various applications.

Author: Conture

—

Double column, hydraulic or screw car lift?

Choosing a lift is a real challenge for the workshop. It is worth equipping the workshop with a lift so that it does not run from and to the channel and that repairs take place in more comfortable conditions. Depending on what is most needed, there are three main types of lifts. We are talking here about a two-column, hydraulic and screw lift. Each of them has its own advantages and disadvantages, which are worth getting to know before we decide to buy.

Versatility, durability or strength

Two-column lifts are very popular, which is due to their universality and relatively low price. The whole works on the principle of trolleys moving on the guides, on which the arms are mounted, which are additionally adjustable in terms of the length of extension. Thanks to this it is possible to lift vehicles with variously arranged support points. The price of this solution depends on the type of drive as well as the possible load capacity. The disadvantage is the lack of access to certain places of the car, e.g. gearbox. There are also works that we will not be able to do with such lifts (e.g. wheel geometry).

In this case, we have hydraulic jacks, which are additionally characterized by extremely quiet and fast operation and reliability. A big advantage is also the very strong support, thanks to which the lifted car is stable.

However, if you are looking for something that will be able to lift or transfer large masses, then nothing works better than a screw jack. It works based on the engine and worm gear. These lifts are also an excellent choice when we care about the speed of lifting, as well as ease of synchronization of drives.

A lift for a small workshop

The task of the elevators is to move away from the duct system and facilitate work. The three types described have their own varieties that can be useful in specific applications. So when looking for a lift for our workshop, it is also good to suggest the opinions of other customers, workshops that use a given type of lift.

Author: Grzegorz Pospieszczyk

Double column, hydraulic or screw car lift?

A lift is an important element of a car workshop. Without it, it’s hard to imagine most of the work, so the decision to buy it can not be accidental. It is necessary to think through it, check the offers and choose a device that will fulfill its task for years.

Before buying – what is important?

The most important thing to think about before you buy a lift is its future use. This seems a trivial matter, but expectations can be different in every establishment. It is important to answer the question how much work the lift will have to withstand, what is the scope of services offered by the plant, what housing conditions are available. It is also important to consider which vehicles are most often serviced, because works related to passenger cars require a different lift than works related to several-tonne vehicles.

Two-post lift

Two-column lifts are one of the available options among this type of equipment. It is a good option if you need a position for various types of work, without having to create new ones for various tasks. Among the features worth emphasizing is the ability to adjust the height of the lift to the current job, as well as to the height of the employee, which adds to the comfort of work. Thanks to two pairs of arms, the two-column lift lifts the vehicle to the desired height allowing for repair work on the chassis.

Hydraulic lift

Another lift that you can choose is a hydraulic lift. Facilitates lifting of heavy objects with the action of the liquid, which pushes one of the parts of the lift causing it to lift. This makes it easier to work with heavy components that require lifting a vehicle or machine part. It can help, but it is less practical compared to a two-column lift.

Screw jack

There are also screw jacks available on the market, which can be used mainly when working with the stage in the theater. They facilitate the raising of stages or rows of chairs in the theater by linearly moving the elements and acting as lifting, lowering, pressure devices.

Author: Piotr Michałowski

What car tire assembly is suitable for low-profile tires?

What car tire assembly is suitable for low-profile tires?

What car tire assembly is suitable for low-profile tires? Choosing a tire changer is a hard task that is best thought through in terms of all the workshop options. Since it depends on what type of tires we can mount on a rim, that is, de facto what customers we serve and which we will send to other workshops. It is worth considering during this digression the fitting intended for low-profile tires.

What car tire assembly is suitable for low-profile tires? Choosing a tire changer is a hard task that is best thought through in terms of all the workshop options. Since it depends on what type of tires we can mount on a rim, that is, de facto what customers we serve and which we will send to other workshops. It is worth considering during this digression the fitting intended for low-profile tires.

The tire changer for low profile tires is a device that deviates from traditional machines. The non-standard tire changer is more massive and is intended primarily for larger tires, such as the low profile and Run Flat tires mentioned above. Their construction usually takes into account the lifter, helpful at the stage of moving the wheels to the area of the assembly table. In addition, the conventional hammer was replaced in their case by pressure rollers (two or single), and the mounting foot is equipped with so-called. “LL system”, based on the use of a characteristic demolition can. This last mentioned factor also allows you to give up the necessity of using spoons. The greatest strengths of this tire removal device are their reinforced structure and optimized speed of work within problematic tires. Among the tire changers for low-profile tires, you can recommend X-36 or X-98 models from the renowned Twin Busch brand known for its unique production processes and strict quality control of its range.

When choosing a fitting, it is worth paying attention to:

- available range of supported tires and table surface (the more extensive, the better, within the limits of course the amount of space available in a given workshop),

- strength of ramming rammer – it should be relatively high if we plan to work hard on hard tires,

- thickness of the assembly column, which determines the durability of the machine during the assembly and disassembly of tires,

- height of the column – in the elevated variants it is significantly easier to service wheels with exceptionally wide rims,

- user manual and certification of a given wheel changer, issued by industry standards organizations,

- possibility of expansion, which will allow us to increase the range of tires supported by our tire shop, eg for low-profile tires or – increasingly used in Poland – Run Flat.

Compressor – Piston or screw?

Compressor – Piston or screw?

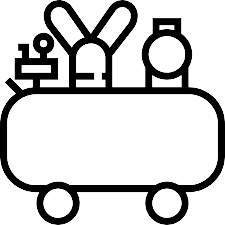

The piston compressor and screw compressor are the two most commonly used solutions in car workshops. There are several subtypes that come from the above two categories, although they are more specialized and adapted to specific tasks. Below we look at the comparison of these compressors.

The cost of purchase and use of the compressor

The cost of purchase and use of the compressor

The piston compressor turns out to be the most cheaper, but these are devices with a very diverse construction. In principle, however, they are rarely as precise and efficient as screw compressors, and their design is simpler, hence often a big difference in price. The operating costs in both cases fall more or less the same, but with the reservation that it depends very much on the quality of the device.

Quality of compressor / compressor operation

Modern piston compressors are much quieter than older models, but almost always louder than screw compressors. The latter is also characterized by a much higher work culture in the start-up phase: less vibrations, less fluctuation of parameters in the initial phase of operation, and the start-up usually does not require excessive energy consumption.

It is worth paying attention to the quality of workmanship: the lower the precision, the higher the noise and the greater vibrations during operation. These parameters can also change after a certain time of operation with wear of parts or micro-damage – what are the standard performance of both types of compressors, you can check on the manufacturer’s website

Energy consumption

Today, both piston compressors and screw compressors are designed in accordance with the principles that allow to reduce the demand for energy in accordance with European Union standards. The fact is, however, that due to the need to obtain better performance parameters, the construction of piston compressors sometimes becomes complicated, and this affects the greater energy consumption. Precisely made screw compressor has less resistance and may be a more economical variant.

What voltage do piston / screw compressors have?

Screw compressors are mostly in the 400V version, although there are 230V versions. This is because screw compressors are used in professional plants. Piston compressors, on the other hand, are characterized by the presence of both versions, 400V and 230V, because they are adapted for private persons and companies.

Mobility

Both reciprocating compressors and screw compressors are produced as stationary models and mobile compressors – in the latter case their construction is modified accordingly. However, obtaining good compression parameters is possible in both cases.

Setting up a workshop – what lift to choose?

Setting up a workshop – what lift to choose?

Setting up a workshop – what lift to choose?

What lift to choose? Choosing a hoist is one of the most common issues among people who are just starting their adventure with mechanics in a company. A considerable difference here can be created by the issue of experience and education in the field of mechanics, although this is only one of several factors that should be taken into account. It is always worth getting acquainted with the full offer of the manufacturer to compare many factors, such as:

- orientation in the operating costs of the device,

- getting expert knowledge about the solutions used in the construction of the lift,

- determining the installation conditions of the lifting device that the manufacturer has provided. Very important, especially at the building design stage. With the need to adapt the existing substrate, it will guarantee its proper preparation,

- determination of service needs at a given position and their confrontation with the usefulness of the lift,

- determining whether a given lift unit promises to expand the scope of services in the future or whether it will require modernization or replacement,

- clarifying the scope of warranty and post-warranty service.

A very helpful issue in the selection of such a machine is very often direct contact with the producer or wholesaler, such questions are usually personalized and will best allow you to verify whether a given lift is created for us.

Among the lifts we distinguish the following types:

Point lifts

Point lifts

The point lift will certainly be the smallest and the minimum device in the workshop. Its small size makes it suitable for virtually any workshop. This variant will work great in tire services, where lifting of the entire vehicle is not required. The kind of point lift used is the discretionary issue. The user will decide whether it should be a pneumatic, pneumatic-hydraulic or hydraulic unit. As for the construction itself, the user’s preferences will also be the main ones here. For example, others in the case of cars with reduced suspension and others in the service of delivery vehicles. In addition to low purchase costs, these types of lifts do not generate high operating costs. If their service, review is necessary, expenses will certainly not be high. If there is a need to replace them due to a significant degree of wear, the purchase of subsequent ones will not be a significant burden. It is also certain that in the course of use in the workshop, they will allow you to generate profits, with a lower commitment of equipment resources.

Single column lifts

Which lift should I choose? Single column lifts are the most frequently chosen workshop equipment for lifting cars in the workshop and may be one of the best to choose from. Particularly useful may be, among others, in bodyshops and typical tire services. These are usually dedicated constructions that allow you to lift one of the sides of the vehicle. Single-column lifts that allow lifting the entire vehicle, will be used wherever it is essential to maintain the passability of the position, beyond the time of his work. Such a solution may also result from ground restrictions, which do not allow permanent fixing of the selected elevator unit. These elevators simultaneously guarantee high work efficiency compared to the cost of purchase and operation.

Two-column lifts

Hoists based on two columns is the first lift, which is permanently mounted in the ground. They are considered safe and ergonomic for their abilities. Currently, we will be able to purchase a lift adapted to all car versions, including for vehicles with low chassis, SUVs, 4×4, etc. In addition, these units are equipped with many useful accessories. This will include instrumentation specialized in the area of support points, column synchronization, as well as extensions and elevations of the entire structure. They enable lifting the whole vehicle to the set height. Their columns are fixed to the ground permanently. The stand equipped with a two-column lift guarantees high throughput and high flexibility of work. Due to unrestricted access to the vehicle chassis, the operator has the possibility to carry out a series of maintenance activities.

Four-column lifts

Four-column lifts are the largest and non-mobile lifts on the list. At the same time, they will prove to be the best alternative for the channels in the workshop. They are perfect for any workshop work on the car. Recommended rather in specialized workshops, but with appropriate configuration will also allow for complementary tire service. They will be used in rooms with appropriate dimensions. The length of the platforms depends on the vehicle category planned for servicing. If the position is to have a developmental character, the correct action will be to choose a unit with a length of 5 meters and more. This will ensure the entry of vans, which are already characterized by significant axle spacing. The user must also foresee that higher vehicles can be served on the station.

If the object is high enough, it does not have to give up full functionality, ie a full range of lifting. With lower objects, it is obvious that the operation of the jack will be compromised in this respect. Although the presence of 4 columns on the bench limits the freedom of movement, it should not negatively affect the ergonomics of its execution and location. The mere fact of lifting vehicles through a 4-column mechanism, however, ensures great safety and comfort of users. The unit is properly leveled and serviced for security, it will certainly allow for trouble-free use. The equipment of such a device is also extremely wide, we can find, for example, recesses for turntables, expansion plates, a subliminal lift and much more.

Scissor lifts – subliminal

Scissor lifts – subliminal

Sublimators are one of two types of scissor lifts. In variants up to 1 m, commonly referred to as “low lift”, you can plan the service on the tire service. To some extent, the subliminal lift will also allow for standard mechanical work with the car. Variants 2 m, commonly referred to as “high lifting”, will allow for much more. It is only necessary to take into account the limited access within the vehicle’s thresholds. The biggest advantage of this type of hoist is the possibility of mounting in a recess in the floor, which will allow it to be completely hidden. If the lift is not used, other service activities can be practically carried out on the entire stand. It is worth noting that these types of units allow for the free placement of the controller. The user can place it on the selected side, and if necessary, even extend the wires of the electromechanical system. The choice of such a unit certainly corresponds to which jack to choose.

Scissor lifts – overrun

The scissor lift platforms should be regarded as the most specialized units on the list of described lifts. When buying, it is worth considering the price and size of such a lift. These certainly require the user to carefully plan the position. At present, you can find almost only scissor lifts based on a scissor mechanism. They damped the tilting mechanisms used in the last century. For leveling and safety, ratchet mechanisms are generally the same and the jack itself works on the principle of hydraulic actuators. Nowadays, the position of pawls on one of the pair of shears is very popular among the manufacturers of such lifts. The installation does not differ from the requirements for four-column or scissor-scissor units. At this point, it should be mentioned that the scissor version of the inrun after assembly in the recess may meet the criteria set out so-called. measuring benches. Turning to functionality, this type of jacks can be equipped with practically the same equipment used in four-column versions.

Again, the question arises – which jack to choose? – First of all, economical, meeting all the necessary requirements, guaranteeing safety and generating profits.

— Michael N. Adam

Which vulcanization machines should I choose?

Which vulcanization machines should I choose?

Running a vulcanization plant is a very good idea for a business that brings relatively large profits despite enormous competition. It is not surprising that there are ever new outlets where you can count on comprehensive tire service – from replacement to repair, maintenance and purchase of new tires. Which vulcanization machines should I choose so that the workshop can start working at full speed?

Indispensable minimum

Indispensable minimum

To start customer service in the field of vulcanization, the necessary equipment is a tire changer. This device is designed to pull and apply tires on rims. When choosing such equipment, pay attention to the wheel diameter that can be handled. The second important element of vulcanization plant equipment is the balancer, whose task is to examine and possibly improve the balance of the wheel – and this affects the proper functioning of the chassis and less wear of the tires. Another necessary equipment is a compressor – it is used to pump the wheels after the replacement. It is also obvious that you need a lift (simple one-column or scissor repair) and a screwdriver that will allow you to remove the wheel.

Further equipment

In addition to the absolute minimum in the vulcanization plant must be found various accessories, such as wheel weights, screws, glues, valves, nuts – in a word, everything that can be useful when repairing and replacing tires. It is also good to invest and create the opportunity to buy tires or rims on the spot, because many customers decide to use such a service. It should also be remembered that man does not live by tires alone, and competition forces a greater range of activities. It is also worth to put on simple repairs, such as replacing brake pads, shock absorbers or oil. Thus, it will be easier to attract customers and encourage them to positive opinions. In this case, the basic tools and a better lift will be necessary.

— Conture

The basic equipment of the car workshop

The basic equipment of the car workshop

The basic equipment of a car workshop is not only a guarantee of comfortable and effective work, but also a business card in the eyes of customers. That is why it is so important to get the right equipment, whose presence is a sign of professionalism and providing services at the highest level. What elements should not be forgotten when starting your own workshop?

Workshop furniture

Workshop furniture

When buying furniture for the workshop, special attention should be paid to their maximum load and durability, because they should be characterized by high resistance to various damages, resulting from the weight of the equipment and the character of the place. In addition, you can not forget about functional trolleys, which are equipped with all the necessary tools and enable comfortable movement around the workshop.

One-column, two-column or four-column lifts?

In the case of this type of devices, you should invest in the highest quality of products, which is supported not only by the comfort of work, but also the safety of the car and human life. Among the vehicle lifts, the most popular models are column models, the use of which depends on the type and needs of the workshop.

Single column structures will work in small plants, and mobile models offer great maneuverability on the surface. The most popular solution are two-column lifts, using two pairs of arms, adjustable jointed, enabling the release of wheels and suspension of the vehicle. On the other hand, four-column constructions constitute an overrun type, in which the vehicle is positioned on the plates, allowing the width of the device to be adjusted to the track width.

Diagnostic devices

In every professional car workshop should be found diagnostic equipment, the amount of which must be conditioned on the individual needs of the plant.

Compressor

In the case of workshops where pneumatic equipment is used, the presence of an oil compressor, which is used to drive them, will be crucial.

We cordially invite you to familiarize yourself with the offer of our company, we will equip every car repair shop!

– Conture

Usable space and, of course, the budget will be the most important factors here. In the case of a small workshop, the scissor lift will do much better, which colloquially says “takes up as much space as nothing.” However, it can be a drawback that scissor lifts are slightly more expensive than column ones. The price is influenced by, among others, comparable performance, compactness sought after by many workshops and a lifting capacity of 5 tons.

Usable space and, of course, the budget will be the most important factors here. In the case of a small workshop, the scissor lift will do much better, which colloquially says “takes up as much space as nothing.” However, it can be a drawback that scissor lifts are slightly more expensive than column ones. The price is influenced by, among others, comparable performance, compactness sought after by many workshops and a lifting capacity of 5 tons.

All machines manufactured by Twin Busch have thought-out and proven safeguards in such a way that the user can operate the garage without fear. For lifts, the most common protection will be a ratchet system on the columns. As soon as the vehicle is raised, press the lock button, which will lock the platform on the “teeth”. If only the user adheres to all established safety rules contained in the manual and general OHS, then there is a 100% guarantee of its safety. All norms and standards are confirmed by world-renowned TÜV, ASA, ISO, WDK and SEMA certificates.

All machines manufactured by Twin Busch have thought-out and proven safeguards in such a way that the user can operate the garage without fear. For lifts, the most common protection will be a ratchet system on the columns. As soon as the vehicle is raised, press the lock button, which will lock the platform on the “teeth”. If only the user adheres to all established safety rules contained in the manual and general OHS, then there is a 100% guarantee of its safety. All norms and standards are confirmed by world-renowned TÜV, ASA, ISO, WDK and SEMA certificates.

The assembly machine is a basic tool used in vulcanization plants. It allows you to remove and install tires on the rims. There are different models for such devices, and everything depends of course on the specifics of the plant. The most versatile are truck tire changers that allow operation on vans tires as well as tractors and other agricultural equipment. What scope of service should have such equipment?

The assembly machine is a basic tool used in vulcanization plants. It allows you to remove and install tires on the rims. There are different models for such devices, and everything depends of course on the specifics of the plant. The most versatile are truck tire changers that allow operation on vans tires as well as tractors and other agricultural equipment. What scope of service should have such equipment?

What car tire assembly is suitable for low-profile tires?

What car tire assembly is suitable for low-profile tires?  The cost of purchase and use of the compressor

The cost of purchase and use of the compressor

Workshop furniture

Workshop furniture